| Mon | Closed |

| Tue |

09:00 14:00 |

- |

12:00 16:00 |

| Wed |

09:00 14:00 |

- |

12:00 16:00 |

| Thu |

09:00 14:00 |

- |

12:00 16:00 |

| Fri |

09:00 |

- |

12:00 |

| Sat | Closed |

| Sun | Closed |

Do you have any questions about the product, installation, delivery or payment? Our friendly and competent service is at your disposal

e-mail

info@maritimusboote.de

Phone number

+49 (0) 38231 402934

to disposal.

Friends / followers / pictures

Facebook: MaritimusYachting

twitter: MaritimusBoote

Picasa Web Albums: Maritime Boats

Skype Internet Phone Name:

maritime_boats

657.40 € *

4,369.70 € *

4,779.00 € *

5,188.00 € *

10,847.00 € *

329.00 € *

4,275.00 € *

193.00 € *

1,162.50 € *

31,573.00 € *

2,764.00 € *

389.00 € *

44.10 € *

122.00 € *

1,114.00 € *

3,491.46 € *

776.00 € *

65.00 € *

495.00 € *

592.00 € *

10,922.00 € *

889.00 € *

1,488.90 € *

85,348.20 € *

1,026.70 € *

124.40 € *

1,125.00 € *

1,598.00 € *

117.20 € *

36.80 € *

65.00 € *

415.90 € *

6,992.75 € *

23,584.20 € *

698.70 € *

1,655.00 € *

104.48 € *

3,475.00 € *

138.20 € *

192.80 € *

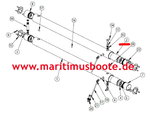

MARITIMUS Boat Online Shop Worldwide Delivery Gear - Marine Gearbox / Transmissions PRM280D2, PRM 280D3, PRM280DP, Ratio 1.96, 2.94, replaces PRM100 PRM101, PRM140, PRM160V, PRM160D...

PRM280D2, PRM 280D3, PRM280DP, Ratio 1.96, 2.94, replaces PRM100 PRM101, PRM140, PRM160V, PRM160D...

In stock

We supply all gear, accessories and spare parts PRM - NEWAGE

PRM marine transmissions have established a world-wide reputation for quality, reliability and in-service performance, making them the ideal choice for pleasure, workboat and fishing vessel applications.

All gearbox components are designed and manufactured for maximum reliability over an extended service life, so when correctly matched to engine and propeller, PRM gearboxes will provide trouble free operation for many years.

A wide range of mounting adapters are available to ensure PRM gearboxes to be fitted to most popular engine models.

All PRM gearboxes allow easy access to major components and service items such as pumps, and hydraulic control valves are conveniently mounted externally. Routine maintenance is limited to checking operating temperature and pressure and inspection of seals and gaskets.

The PRM280 marine gearbox is purpose built for use in both pleasure craft and commercial boats; its twin countershaft design provides separate oil-operated multi-disc clutches (which need no adjustment) for ahead and astern drive allowing full rated power to be transmitted continuously in either direction.

The PRM280 is offered in two different configurations; power take off (PTO) (PRM280DP) and with offset output shaft (PRM280).

A choice of 1.96:1 and 2.94:1 reduction ratios is available; each will provide left-hand or right-hand propeller rotation in "ahead", making the PRM280 particularly well suited to twin engine installations.

The gearcase is constructed of high grade cast iron, internally ribbed for rigidity and strength, and consists of two separate halves to facilitate servicing, the oil pump and hydraulic control valves being externally mounted for easy accessibility.

The PRM280DP live PTO gearbox specifically designed for driving hydraulic pumps to SAEJ774C series B specification. The maximum power which can be transmitted is 22kW (29.5hp) per 1000 rpm.

The hydraulic operating system functions on normal lubricating oil of the same viscosity as that used in the engine, avoiding the need to use automatic transmission fluid, and ensures rapid response to movements of the operating lever for good boat handling. The operating lever has a positive neutral detent and is suitable for use with proprietary single lever remote control operating systems.

Robust and reliable, the hydraulic system is nevertheless provided with a mechanical lock-up device for added security, so that in the unlikely event of hydraulic failure the boat can be brought safely back to port. Access to this device is via a detachable cover located on top of the main gearcase.

A trolling valve can be fitted. This is electronically operated which allows variable speed of the propeller to zero whilst allowing a maximum engine speed of up to 1200 rpm.

Nominal Power Ratings, PRM 280 Marine Gearbox

|

Model |

Ahead Ratio |

Pleasure |

Light Commercial |

Heavy Commercial |

|||

|

kW |

BHP |

kW |

BHP |

kW |

BHP |

||

|

280D2 |

1.96:1 |

2.93 |

3.93 |

2.83 |

3.79 |

2.67 |

3.58 |

|

280D3 |

2.94:1 |

2.93 |

3.93 |

2.83 |

3.79 |

2.67 |

3.58 |

Maximum operating speeds:

4500 rev/min intermittent, 4000 rev/min continuous

Note: These powers have been measured at the engine flywheel. Ratings have been established to ensure the long trouble free life of the gearbox which should not, therefore be used at powers in excess of those shown.

Operating Pressure

Minimum - 20.00 bar (290 lb./in²), Maximum - 22.06 bar (320 lb./in²). Two tapped holes 1/8" BSP on the top, and M18 on the side of the valve block are provided so that the pressure gauge can be fitted if required.

Oil Cooling

The normal operating temperature of the oil should be in the 50°C - 80°C range and should not be permitted to exceed 90°C. An oil cooler is necessary to ensure that correct operating temperatures are maintained, and the valve block is provided with two 3/8" BSP connectors to allow it to be fitted.

Propeller Thrust

Both ahead and astern thrust is carried by the output shaft bearings which are of adequate capacity for all factory approved ratings.

Propeller Free Wheeling

The PRM280 output shaft can be rotated continuously with the gearbox in neutral. It is therefore not necessary to fit a propshaft brake in such applications.

Approximate Weight & Oil Capacity

|

Approximate dry weight |

PRM280D |

48kg (106lb) excluding adaptor, drive coupling and oil cooler |

|

PRM280DP |

54kg (120lb) excluding adaptor, drive coupling and oil cooler |

|

|

Oil capacity |

1.5 litres (2.64 pints) plus the amount require to fill the cooling circuit |

|

Flexible Input Couplings for PRM280D & PRM280DP

|

Part Number |

Outside Diameter |

Mounting Hole Pattern |

Remarks |

|||||

|

mm. |

in. |

No. |

Diameter |

Pitch Circle Dia. |

||||

|

mm |

in |

mm |

in |

|||||

|

MT1224 |

241.3 |

9.500 |

8 |

8.74 |

0.344 |

222.3 |

8.750 |

SAE 7 ½ in |

|

MT1222 |

314.3 |

12.375 |

6 |

Multi Punched, Dimensions on application |

|

|||

|

8 |

9.53 |

0.375 |

295.3 |

11.625 |

SAE 10 in |

|||

|

MT1162 |

352.4 |

13.875 |

8 |

10.99 |

0.433 |

333.4 |

13.125 |

SAE 11 ½ in |

|

MT1213 |

362.0 |

14.250 |

6 |

8.13 |

0.320 |

295.3 |

11.625 |

Perkins 4-236 |

|

6 |

Multi Punched, Dimensions on application |

|

||||||

|

MT4911 |

352.4 |

13.875 |

8 |

10.99 |

0.433 |

333.4 |

13.125 |

SAE 11 ½ in |

|

MT4912 |

362.0 |

14.250 |

6 |

8.13 |

0.320 |

295.3 |

11.625 |

Perkins 4-236 |

|

6 |

Multi Punched, Dimensions on application |

High Deflection |

||||||

|

MT4913 |

314.3 |

12.375 |

6 |

Multi Punched, Dimensions on application |

|

|||

|

8 |

9.53 |

0.375 |

295.3 |

11.625 |

SAE 10 in |

|||

|

MT4914 |

241.3 |

9.500 |

8 |

8.74 |

0.344 |

222.3 |

8.750 |

SAE 7 ½ in |

|

MT1468 |

362.0 |

14.250 |

6 |

Multi Punched, Dimensions on application |

(for 260C) |

|||

Adaptor Flanges For PRM280D & PRM280DP

|

Part Number |

Description |

Weight |

|

|

kg |

lb |

||

|

MT8074S/A |

SAE2 adaptor flange |

13.0 |

28.7 |

|

MT854S/A |

SAE3 adaptor flange |

11.0 |

24.3 |

|

MT1210S/A |

SAE4 adaptor flange |

10.0 |

22.0 |

|

MT1209S/A |

SAE5 adaptor flange |

7.0 |

15.4 |

|

MT1426S/A |

B/W (Velvet Drive) adaptor flange |

4.3 |

9.5 |

Other Accessories For PRM280D & PRM280DP

|

Part Number |

Description |

Weight |

|

|

kg |

lb |

||

|

MT913S/A |

Oil cooler |

1.2 |

2.6 |

|

MT915 |

Oil pipes (pair) |

0.5 |

1.1 |

|

MT784 |

Oil cooler mounting bracket |

0.2 |

0.4 |

|

MT771 |

Tail shaft half coupling (pilot bored) |

2.5 |

5.5 |

|

MT1104 |

Tail shaft flexible coupling |

1.5 |

3.3 |

|

MT0214 |

Neutral safety start switch |

0.04 |

0.1 |

|

MT5036 |

Oil pressure gauge (direct mounting) |

0.1 |

0.2 |

|

MT0579 |

Power take off |

6.0 |

13.2 |

Service Classification Definitions - Pleasure

Limited to planing hull pleasure craft; operation at full engine throttle should not exceed 5% of total time, with balance of usage at 90% of full throttle engine speed, or less. Maximum operation 500 hours per year. The selection of PRM marine transmissions according to this classification for any commercial boat, or in sport-fishing charter boats or in long range pleasure cruisers, is not approved.

Service Classification Definitions - Light Commercial

Planing or semi-displacement craft used in pleasure or commercial applications may qualify for light commercial rating if annual usage is less than 1500 hours and full throttle operation is limited, with most operating time at partial throttle.

Service Classification Definitions - Heavy Commercial

PRM Newage Limited recommends that all displacement and semi-displacement craft used for commercial applications should be classed as heavy commercial duty. In vessels of this type (including trawlers, purse seiners, lobster and crab boats, tugs, ferries, offshore supply boats etc.) the marine gearbox is expected to work at full governed engine speed. The power setting of the engine must be known and must be within the gearbox's permissible heavy commercial rating.

Important Note

- It is essential for the engine, transmission model, reduction ratio and propeller size to be correctly matched so that the engine can attain its rated speed appropriate to the relevant service classification without labouring.

It is also necessary to ensure the torsional compatibility of the complete propulsion system from engine through to propeller, since disregarding this may result in gear noise, particularly at low speed operation, and may even result in damage to the engine as well as the transmission components.

PRM Model - Replaced By Oil

PRM Delta February 1997 PRM 150D 15W40

PRM 80 September 2016 PRM 90D** ATF Dextron II or III

PRM 120 September 2016 PRM 125D** ATF Dextron II or III

PRM 100 August 1973 PRM 280D 15W40

PRM 101 August 1982 PRM 280D 15W40

PRM 140 December 1978 PRM 280D 15W40

PRM 160V March 1990 PRM 280D** 15W40

PRM 160D March 1997 PRM 280D** 15W40

PRM 260D April 2016 PRM 280D** 15W40

PRM 175 August 1973 PRM 500D 15W40

PRM 250 March 1973 PRM 500D 15W40

PRM 265 January 1978 PRM 500D 15W40

PRM 310V December 1984 PRM 500D** 15W40

PRM 301M April 1987 PRM 500D** 15W40

PRM 302D February 1997 PRM 500D** 15W40

PRM 401M March 1987 PRM 750D** 15W40

PRM 402D April 1997 PRM 750D** 15W40

PRM 601S February 1984 PRM 1000D** 15W40

PRM 601M January 1988 PRM 1000D** 15W40

PRM 601D February 1997 PRM 1000D** 15W40

Items marked ** are a direct replacement for the old model with the same external dimensions.

Oil

A mechanical gearbox (PRM 60, 80, 90, 120 or 125) must use automatic transmission fluid (ATF) Dextron II or III

Hydraulic gearboxes use 15W40 mineral (not synthetic) for typical use. For extreme temperatures see owners handbook.

Always check the oil level with the dipstick screwed down.

Refer to workshop manual for more details.

IMPORTANT NOTICE: ONLY REMOVE BREATHER, DIP STICK, OIL DRAIN PLUG OR OIL LEVEL PLUG ONCE THE GEARBOX IS AT AMBIENT TEMPERATURE. REMEMBER HOT OIL CAN CAUSE BURNS – WORK SAFELY.

Accessories

| Product | Note | Status | Price | ||

|---|---|---|---|---|---|

|

|

2,290.00 € * | |||

|

|

2,290.00 € * | |||

|

|

2,239.00 € * |

Delivery weight: 40 kg

|

||

|

* Prices incl. VAT, plus Shipping

Display accessory details

|

|||||

We also recommend

|

PRM Transmission Kit, PRM 150D2 reduction 2.09:1, including cooler, damper plate etc.

2,239.00 €

*

Delivery weight: 40 kg

|

Browse these categories as well: Gear - Marine Gearbox / Transmissions, PRM gear, Home MARITIMUS Boat Shop, Worldwide delivery, delivery of leading brands, Special Deals May, Spezial Deals 2024

![SEB00035AA Isotherm Thermistor ASU 3,5m isoherm 39228]](/WebRoot/Store7/Shops/289397/63D7/D538/CE5F/29FC/72C1/0A0C/6D0D/9FE5/SEB00035AA_Isotherm_Thermistor_ASU_35m_isoherm_39228_93__MARITIMUS_2_h.jpg)

PRM Transmission 150D1.5 reduction 1.53:1

PRM Transmission 150D1.5 reduction 1.53:1 PRM Transmission 150D3 reduction 2.83:1

PRM Transmission 150D3 reduction 2.83:1 PRM Transmission Kit, PRM 150D2 reduction 2.09:1, including cooler, damper plate etc.

PRM Transmission Kit, PRM 150D2 reduction 2.09:1, including cooler, damper plate etc.